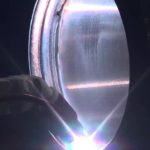

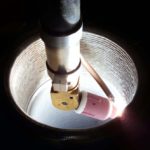

Using specialized equipment, W.H.S. has the ability to coat the inside diameter of full length pipes up to 6 meters. This process requires the use of specialized high definition video monitoring equipment to visualize the weld. These cameras require the use of high-flow refrigerant to protect the equipment from extreme heat inside the tube. W.H.S. has spent years developing custom accessories to make this process repeatable and deliver the highest quality. In addition to the ability to coat the pipe ID, W.H.S. has also developed specialized NDE equipment to perform visual and liquid penetrating examinations inside the coated tube. This machine also has high definition video equipment designed to measure any defects found using calibrated software.

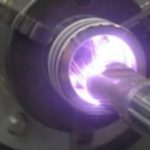

GTAW Pipe Coating – The GTAW pipe coating process provides the highest quality, plus the ability to coat pipes with an ID of just 80mm for parts up to 1.5m in length. There are very few processes and techniques available to coat this small diameter and W.H.S. has created cutting-edge accessories to make this process repeatable. This process also uses two welding heads so that two layers of coating can be applied in one step, which helps improve efficiency and price. For even smaller applications we have developed a process to coat up to an internal diameter of 40mm with a limitation of 50cm in length.

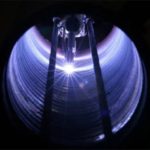

SAW and GMAW Pipe Coating: These processes are reserved for larger diameter applications where accessibility is not an issue. Although these processes can be performed on a minimum diameter of 200 mm, they are typically reserved for applications on internal diameters greater than 600 mm and lengths up to a maximum of 1 m. These processes are also more efficient than GTAW coating which helps lower prices for the right applications.

Coating processes of pipes

- GTAW-P-HW (pulsed hot wire for gas tungsten arc welding)

- SAW (Submerged Arc Welding)

- GMAW (Gas Metal Arc Welding)

Materials for pipe lining

Materiali di base